QUALITY ASSURANCE

Wayne Manufacturing’s dedication to quality starts with the design of the tooling and continues through the process development and manufacturing stage. Custom build gaging and electronic measuring devices are used to ensure part compliance and capability. The quality system has been design to meet current automotive standards and customer specific requirements.

Regular management meetings are held to address continuous improvement ideas and strategies. Employee meetings are conducted to discuss performance and opportunities for improvement also.

Quality

Full Layout Capabilities

A large Ziess CMM is used for complete layout measurements of components and Assemblies.

Quality

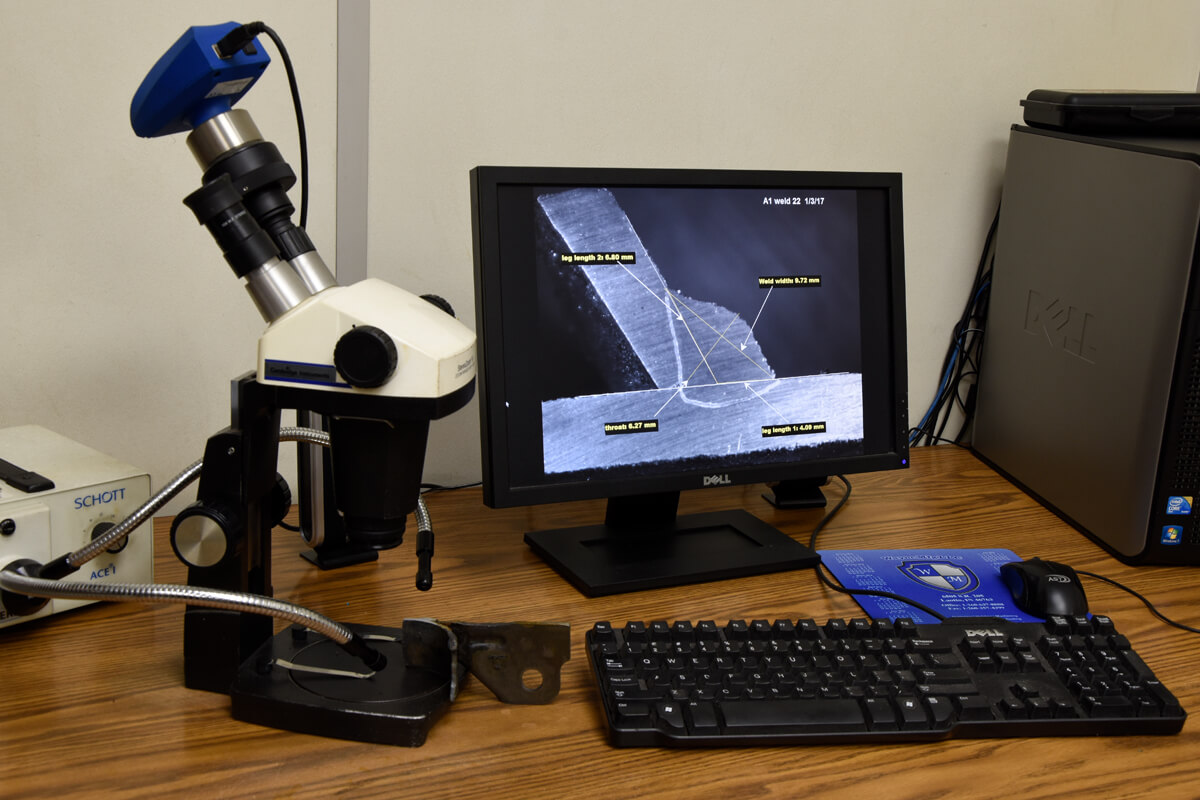

Weld Quality

IATF 16949:2016 Certified

IATF 16949:2016 Certified

Wayne Manufacturing’s Quality Management System is proudly certified by NSF-ISR for IATF 16949:2016 standard. This scope includes conformance in metal stamping with robotic welding, machining and assembly capabilities.